620-16XD Commercial Feed Mixer

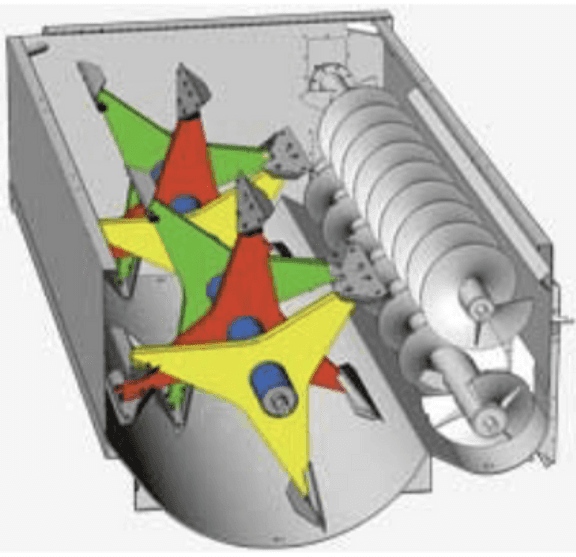

GeneRation II Staggered option is ideal for feeding rations that require wet distillers grains. Improved lifting and tumbling action, less revolutions, faster mix saves time and lowers maintenance costs.

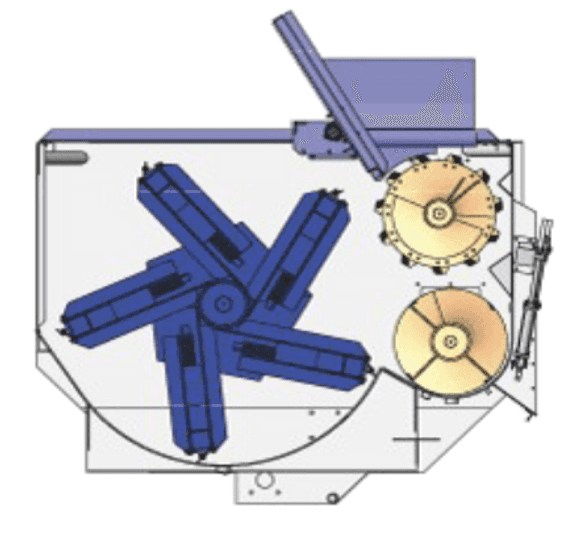

5 or 6 Bar option allows for more leaves and more flakes. The patented rotor lifts feed up to the side augers that move feed from end to end for thorough mixing. This option is preferred in beef operations not using wet distillers grains.

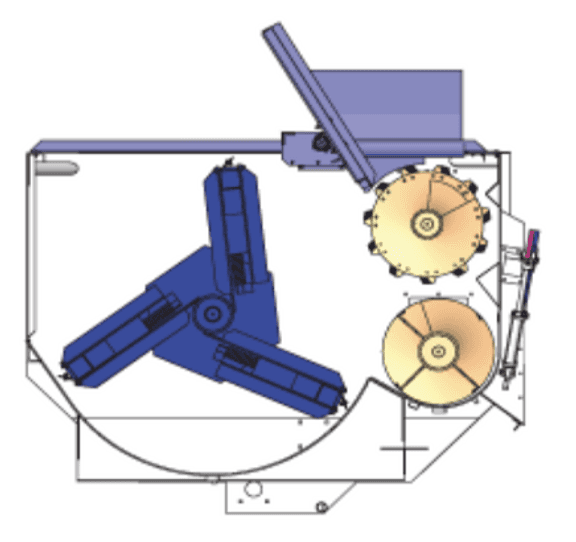

3-Bar option allows more leaves and particle length during mixing with hay - a preference when feeding in dairy options.

| - Specifications Table - | Truck | Trailer | Stationary | All Types |

|---|---|---|---|---|

| Length (cm) | 218"-(554)cm | 278"-(706)cm | 231"-(587)cm | |

| Width (cm) | 113"-(287)cm | 113"-(287)cm | 113"-(287)cm | |

| Height (cm) | 116"-(295 36-91.3)cm | 111"-(280)cm | 86"-(217)cm | |

| Weight (kg) | 16380 lbs-(7428)kg | 18130 lbs-(8222)kg | 16090 lbs-(7296)kg | |

| Capacity-Mixing (m³) | 620 cu. ft-(17.56)m³ | |||

| Maximum Heavy Ration (kg) | 17500 lbs-(7938)kg |