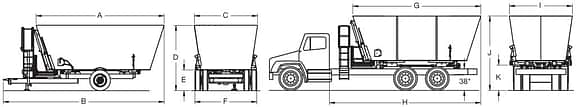

745 Vertical Feed Mixer

| - Specifications Table - | Truck | Trailer | Stationary | All Types |

|---|---|---|---|---|

| Length (cm) | 220-559 | 280-711 | 278-706 | |

| Width (cm) | 108-274 | 110-279 | 108-274 | |

| Height (cm) | 121-305 | 105-265 | 105-265 | |

| Weight (kg) | 13598 to14000-6169 to 6350 | 15200-6893 | 15200-6893 | |

| Capacity-Mixing (m³) | 740-20.95 | |||

| Maximum Heavy Ration (kg) | 18500-8392 |