Roto-Mix

Designed for Feeding Performance

Roto-Mix

Designed for Feeding Performance

Designed for Feeding Performance

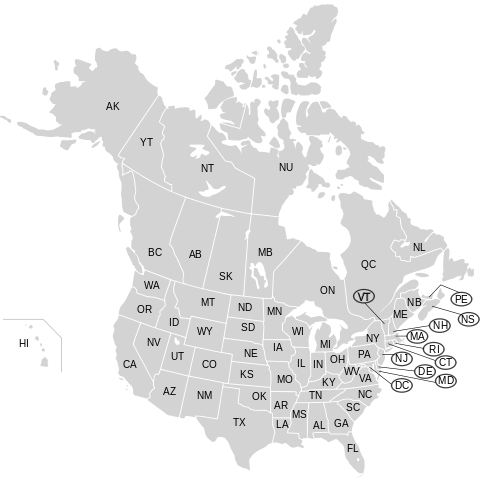

Rotomix is the leader in feed mixers, feed delivery boxes, compost mixing and manure spreading. Discover the wide variety of available products for your needs. We would love to hear from you about how we can help you get the best mixing and spreading performance, find a representative below or contact us directly.

Contact Us

Roto-Mix

2205 East Wyatt Earp Blvd.

P.O. Box 1724

Dodge City, KS 67801

(620) 225-1142

Fax: (620) 225-6370

To request further information please fill out the form on our contact page and a Roto-Mix representative will contact you.

Featured News Article

Auto-Feed System

Auto-Feed System™ Automation for Commercial Feed Delivery The new Auto-Feed System is designed for...

Read More...Roto-Mix Announces their 40th Anniversary!

January 2, 2024 Dodge City, KS Roto-Mix, LLC Celebrates 40 Years in business! Roto-Mix is proud to...

Read More...Roto-Mix names new President and Promotions

December 16, 2019 Dodge City, KS Roto-Mix names new President and Promotions Roto-Mix, LLC, a...

Read More...